https://www.gibidimotors.co.uk/gibidi-floor-810-812-824-830-850-854-880-884

THE GIBIDI ELECTRIC GATE AUTOMATION SPECIALIST

We replace broken non working motors also install on existing gates or completely new installations

2021 The Year For GIBIDI Automation

Office 01773 719347 Sales from 9 to 5 Adrian 07971 475781

If you need product support You will be asked for invoice no and serial no

so have them ready if you need support!

Unlike other hydraulic underground motors the oil is for the life of the Gibidi Floor underground motors and you don't have to change or top up the oil every 2 - 4 years! Like you DO with SEA & BFT hydraulic underground motors

No Such thing as a direct replacement for a Gibidi Floor motor That isn't Gibidi

-

-

-

-

810 or 830 motor replacement gibidi

810 or 830 motor replacement gibidi

810 or 830 motor replacement gibidi

810 or 830 motor replacement gibidi

-

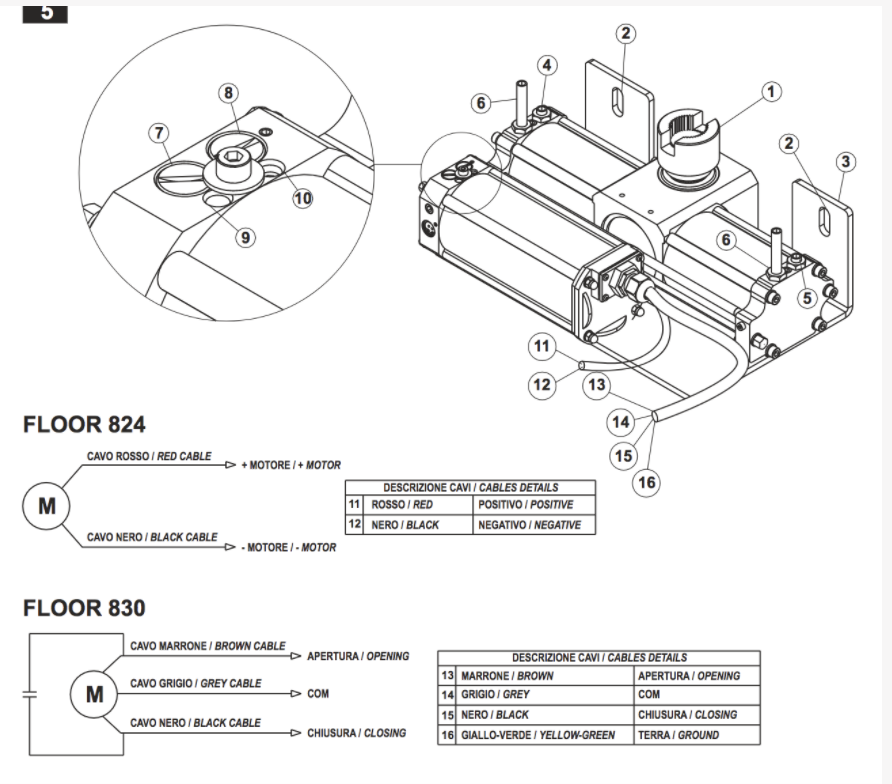

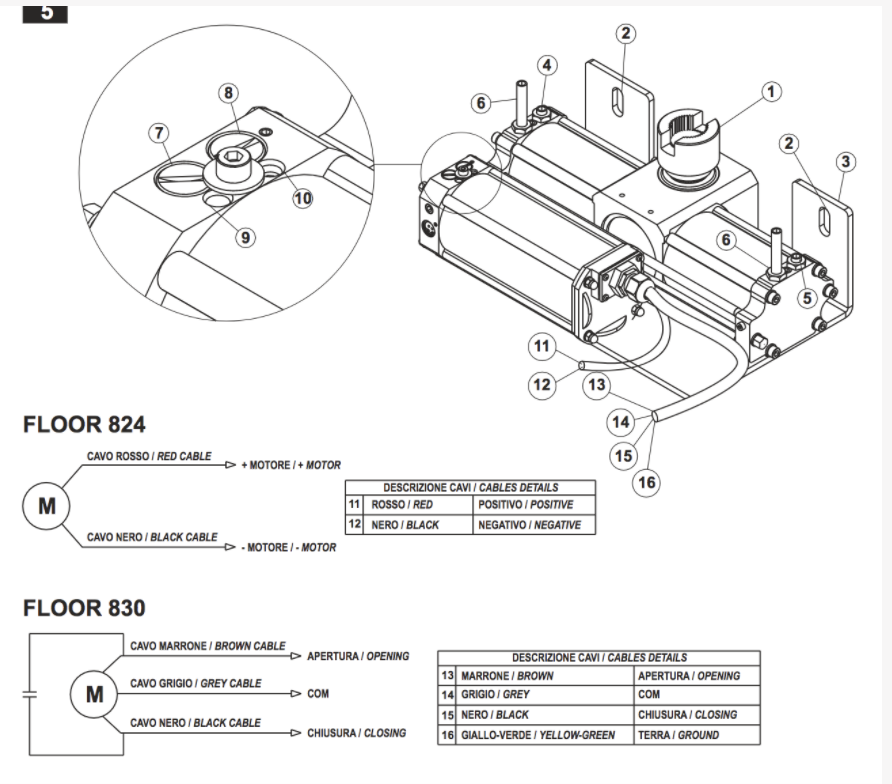

gibidi electric gate automation 824 motor

gibidi electric gate automation 824 motor

gibidi electric gate automation 824 motor

gibidi electric gate automation 824 motor

-

gibidi electric gate automation 810 motor

gibidi electric gate automation 830 motor

gibidi electric gate automation 810 motor

gibidi electric gate automation 830 motor

-

-

-

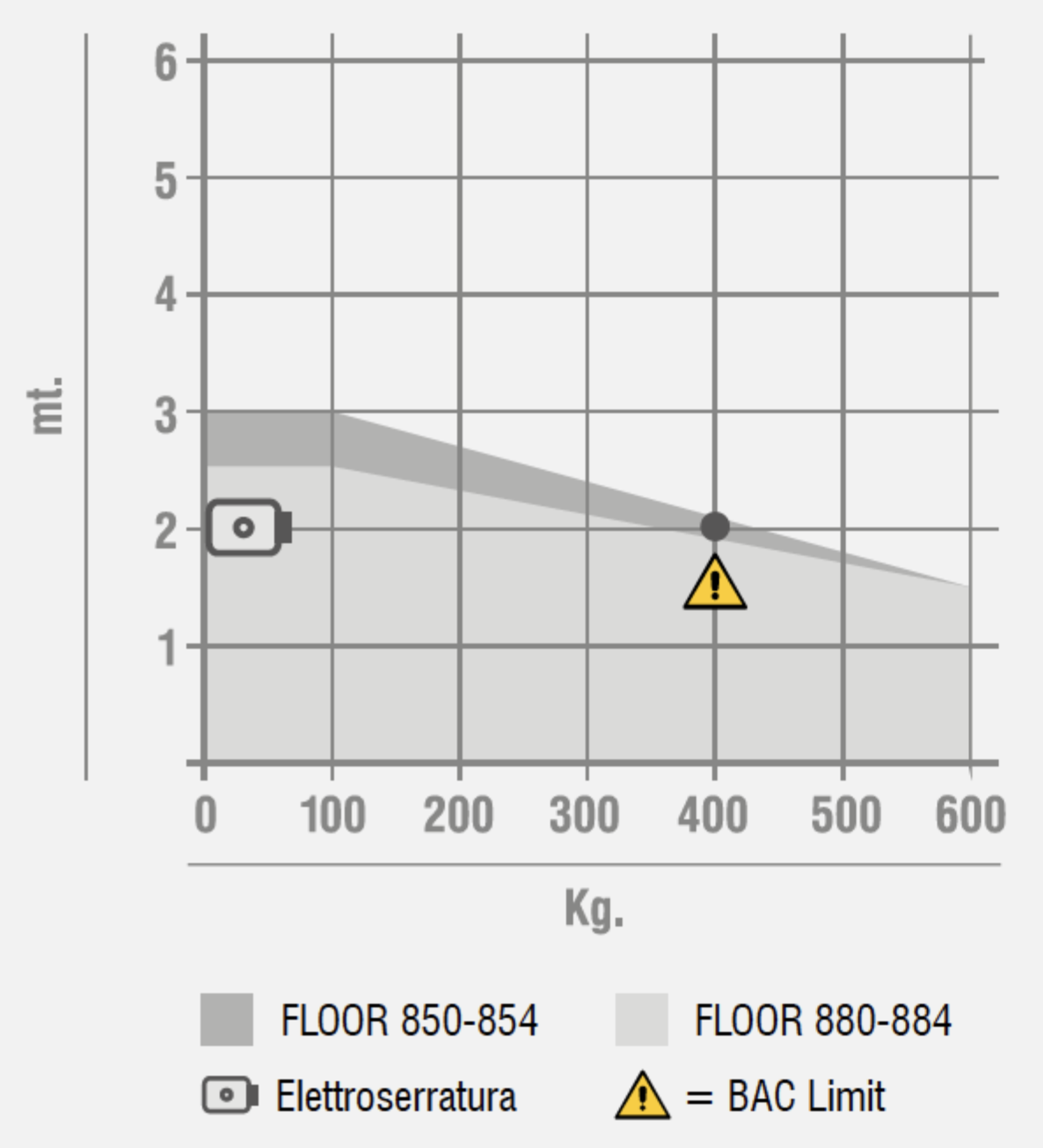

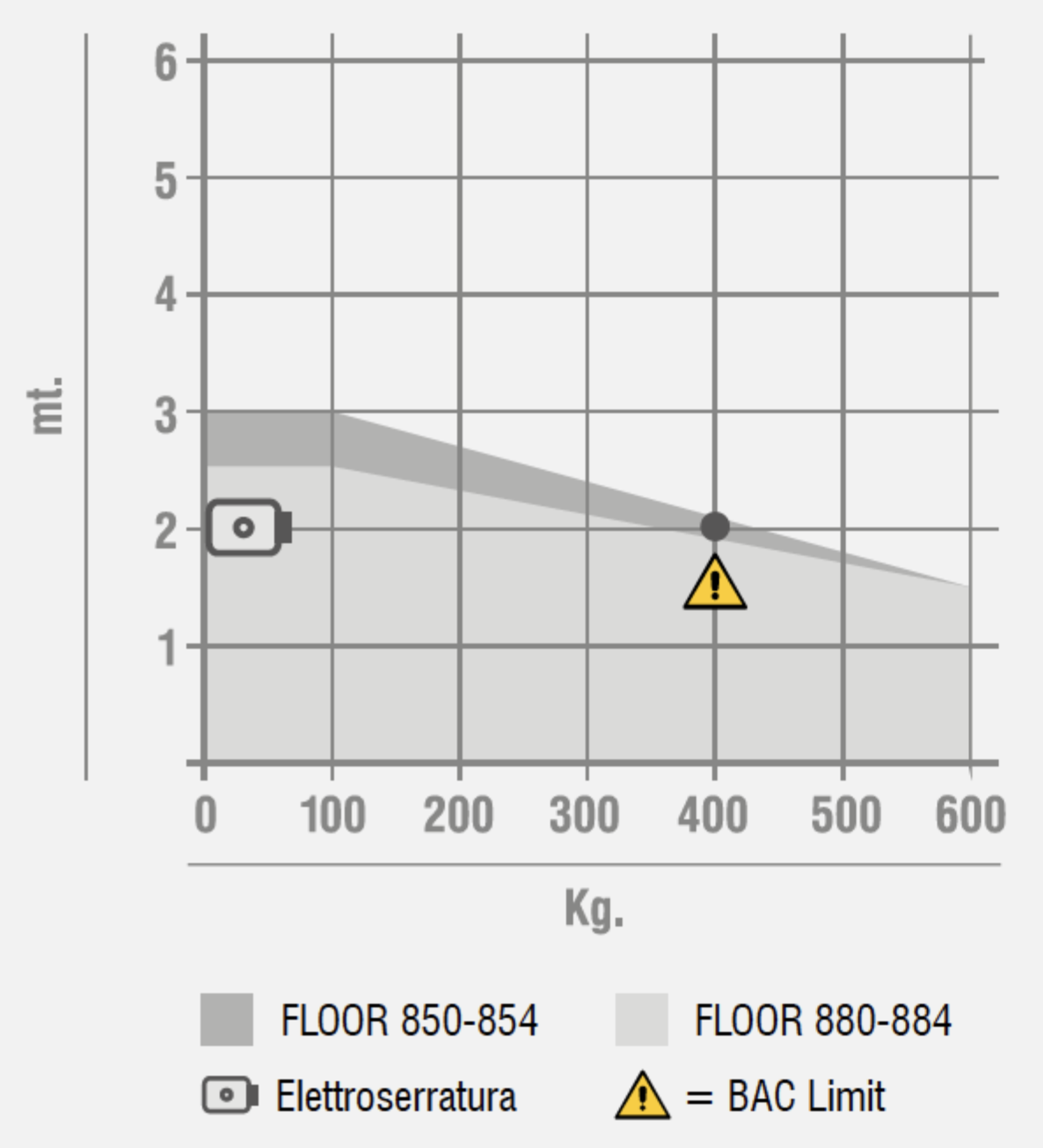

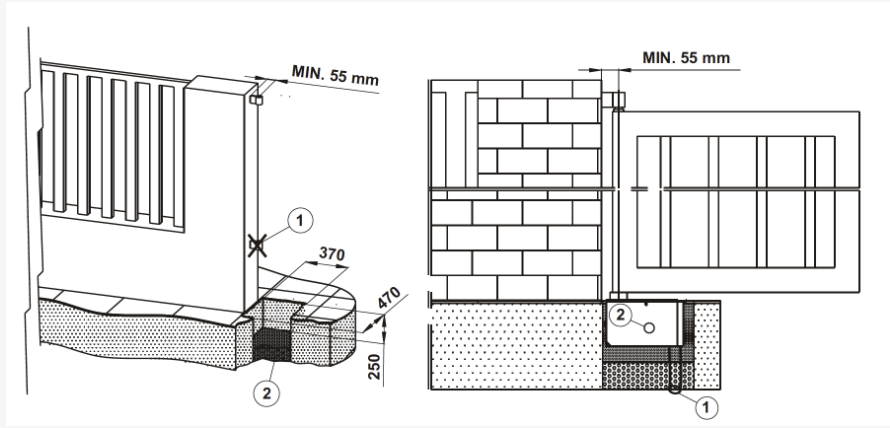

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS LOTS OF STOCK NEW FLOOR 850 AND FLOOR 880

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS LOTS OF STOCK NEW FLOOR 850 AND FLOOR 880

-

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS

-

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS

-

-

-

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS

-

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS

-

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS

-

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS

-

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS

-

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS

-

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS

Don't know the parts you need text, email or whatsapp a picture to Adrian on 07971475781 or email mail@arsparks.co.uk with a picture of the broken part or a picture from the back of your gates with a description of the problem and we will do what we can to help

.

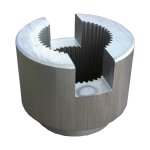

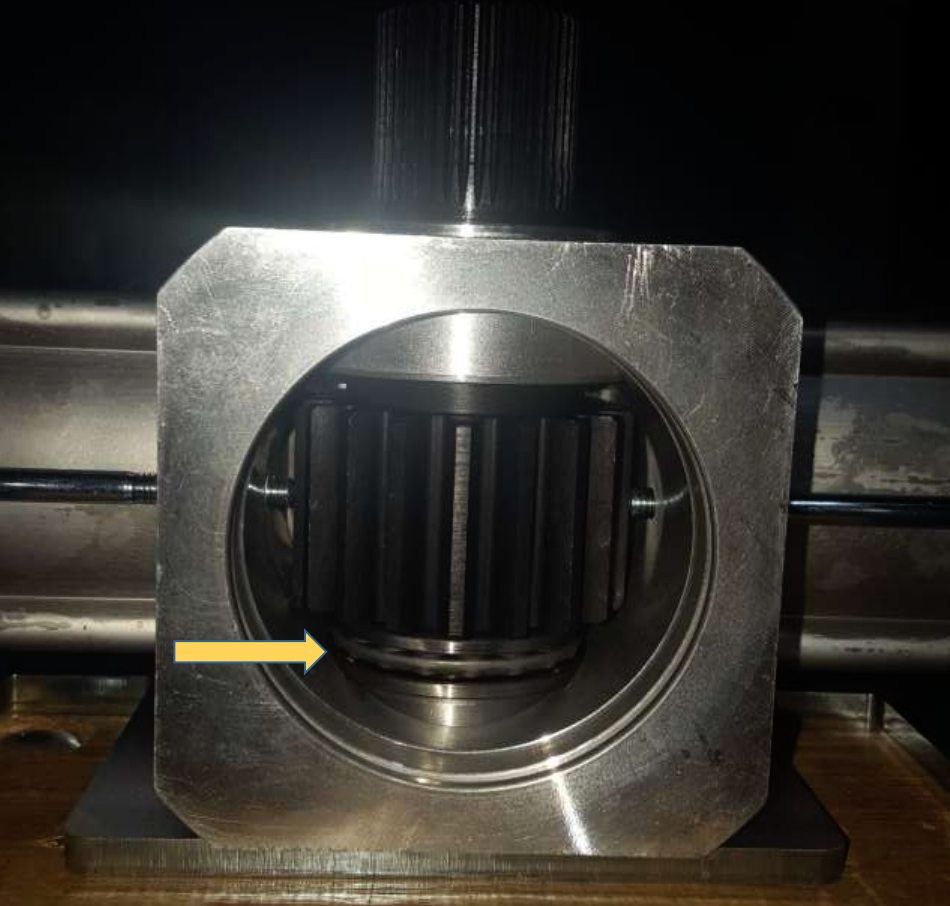

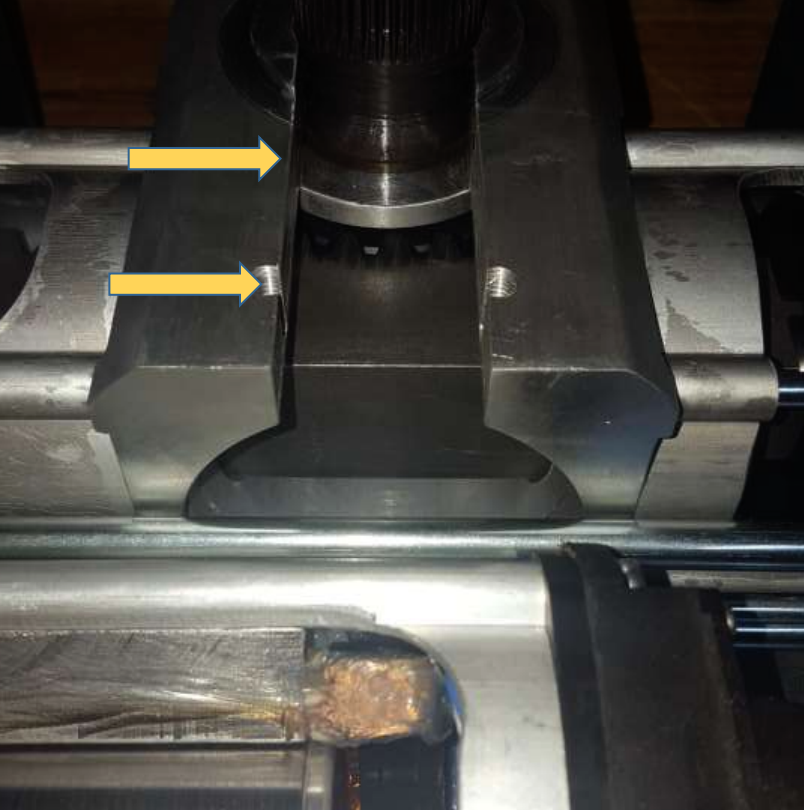

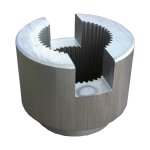

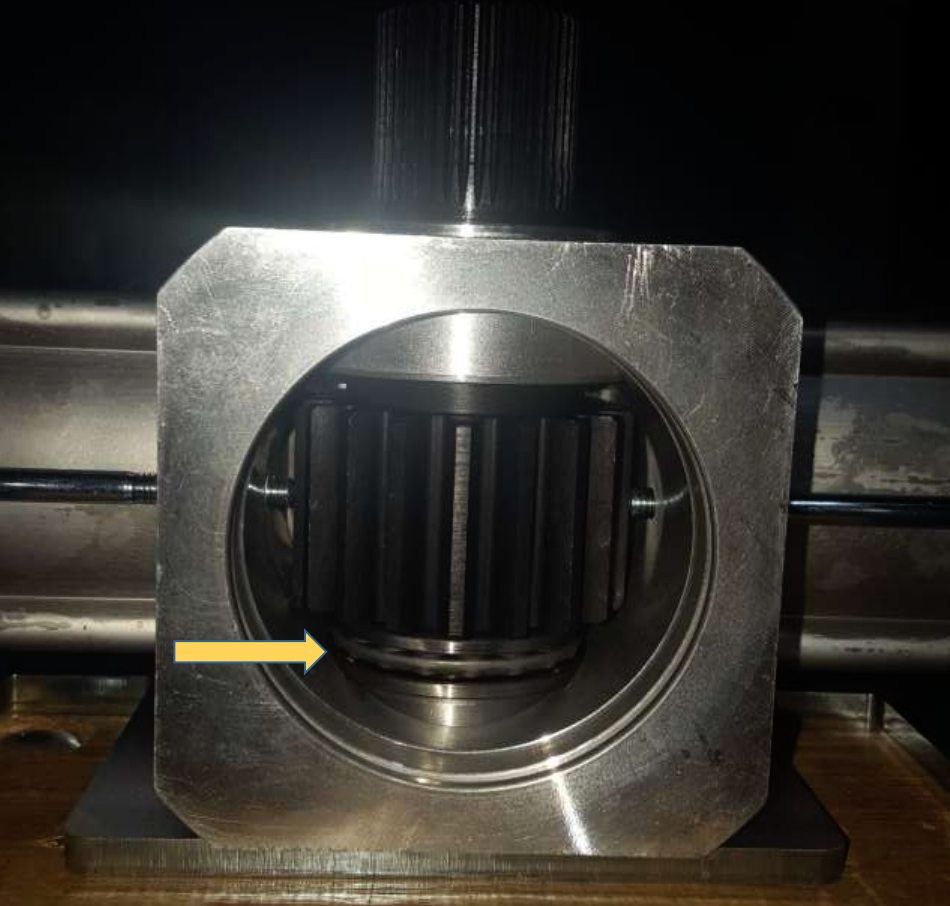

BELOW IS A WORN TOP BOSS

Above is one of the most common things you see with the top boss with age or if the boss was greased when installed as its a non greased part!

ABOVE TOP BOSS WORN

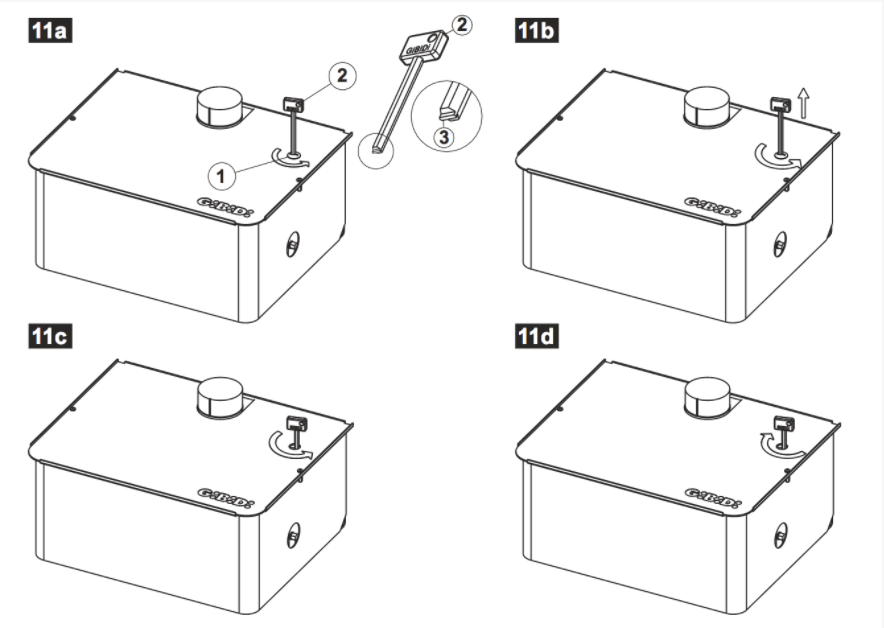

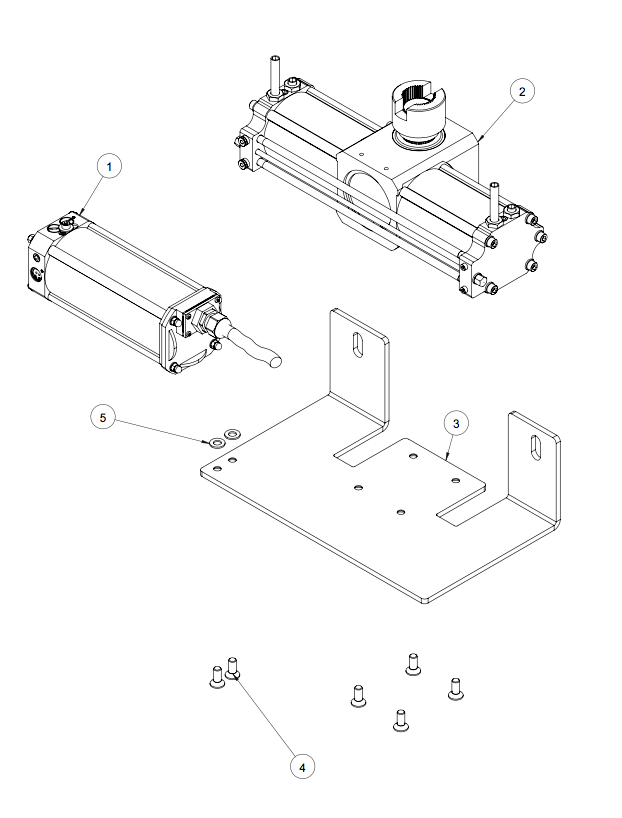

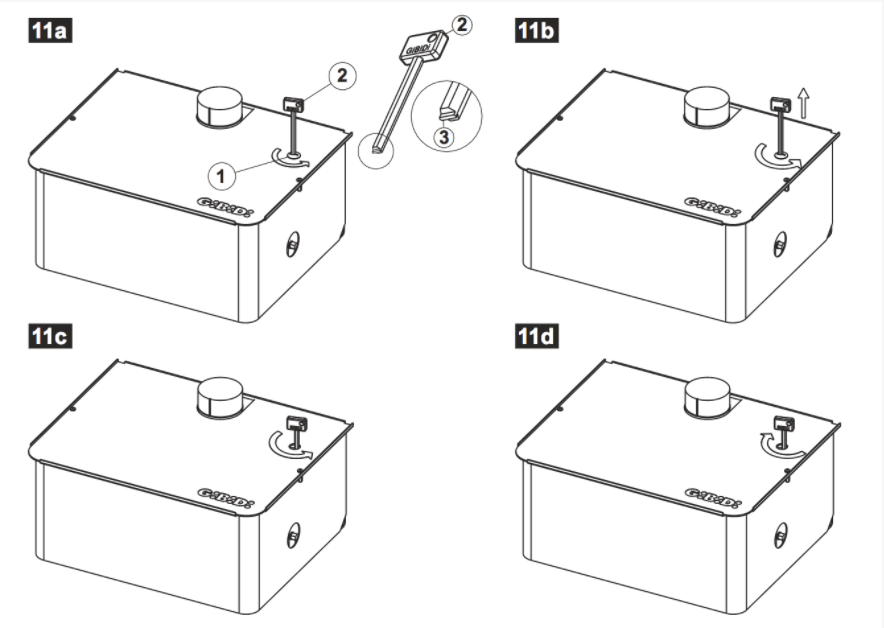

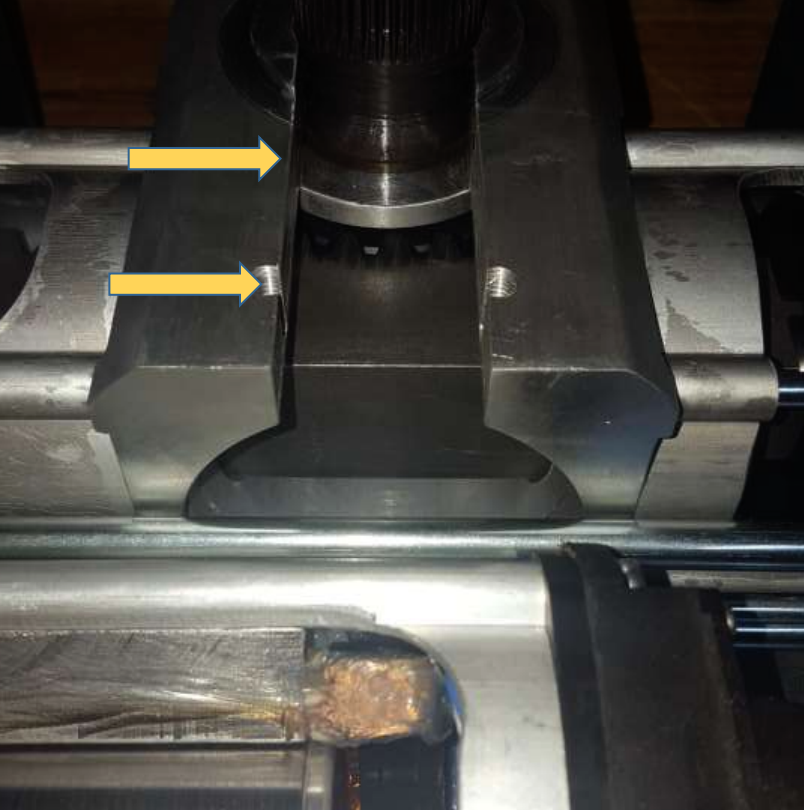

Old 810 to new 830 replacement this is how to do it

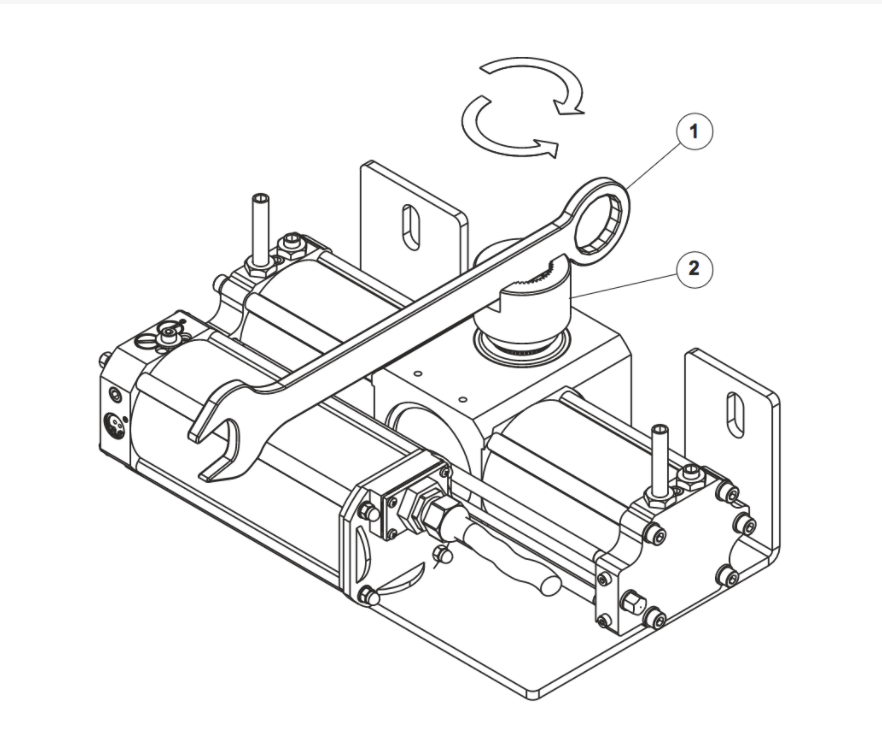

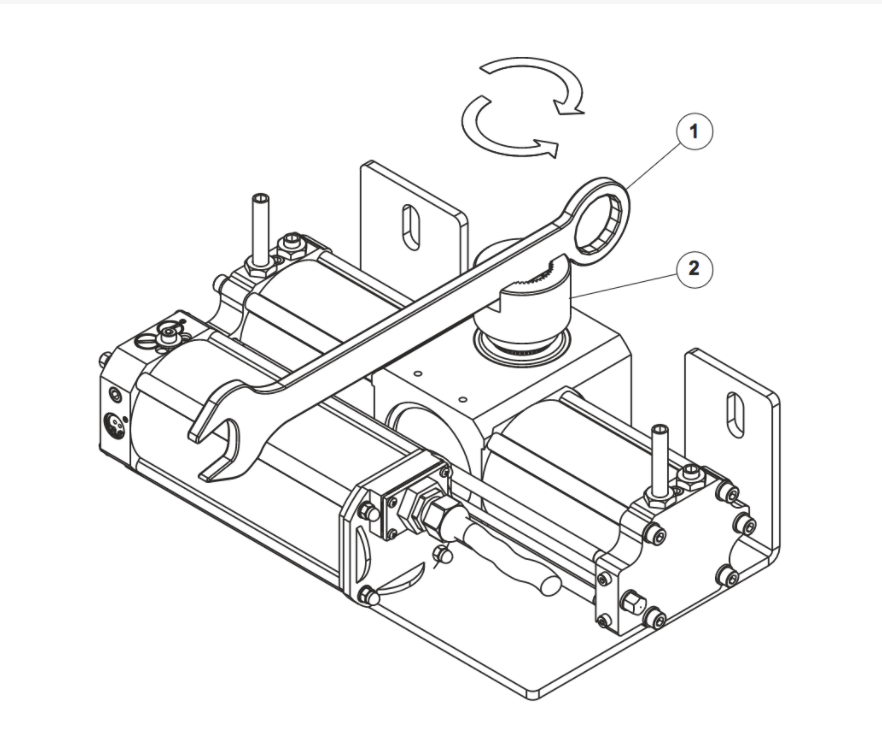

1, Turn slot so its facing front by turning manual release 1/2 a turn anti clockwise

Replace motor with the bottom boss in the correct place {the motor can do 180 deg so put the bottom boss in correct place for the gates to hit stops open and close.... replace 19mm bolts , wire as before, turn power off for 10 seconds then back on , give gates a command the gates should open, {if they close swap lives over brown and black}

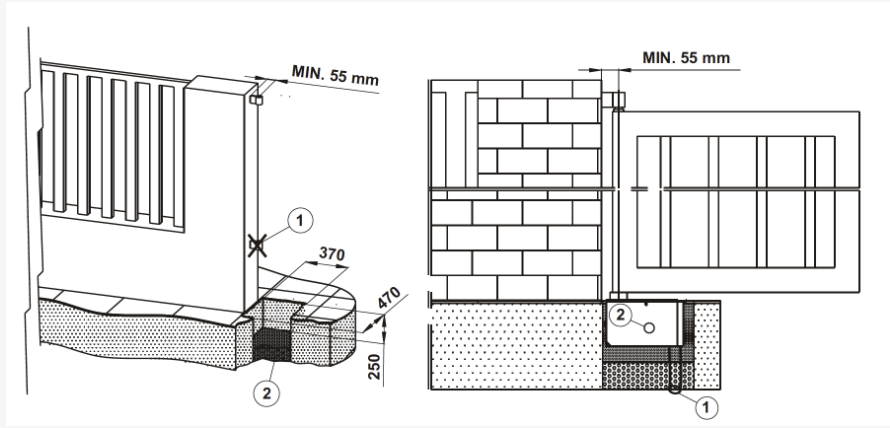

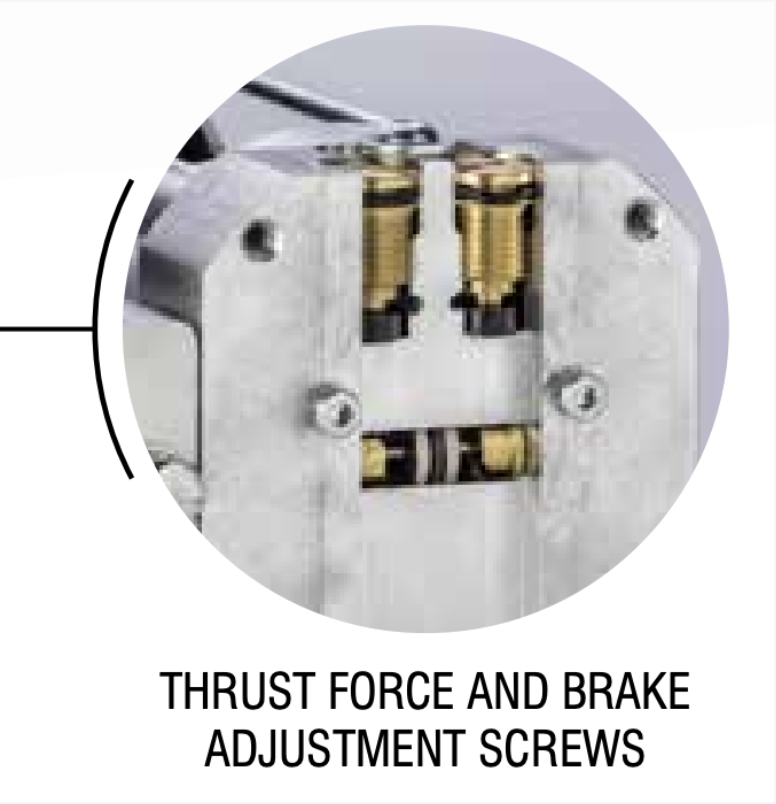

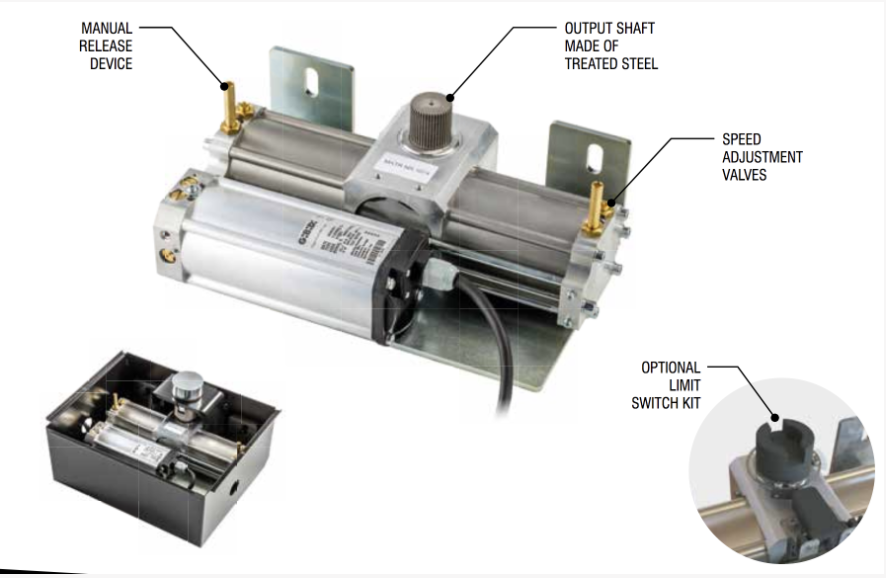

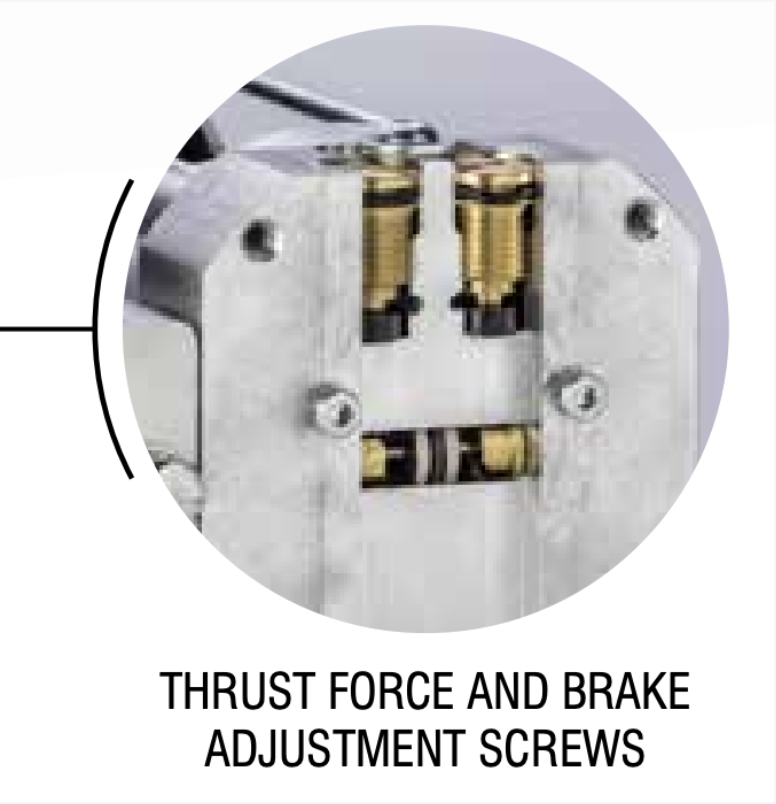

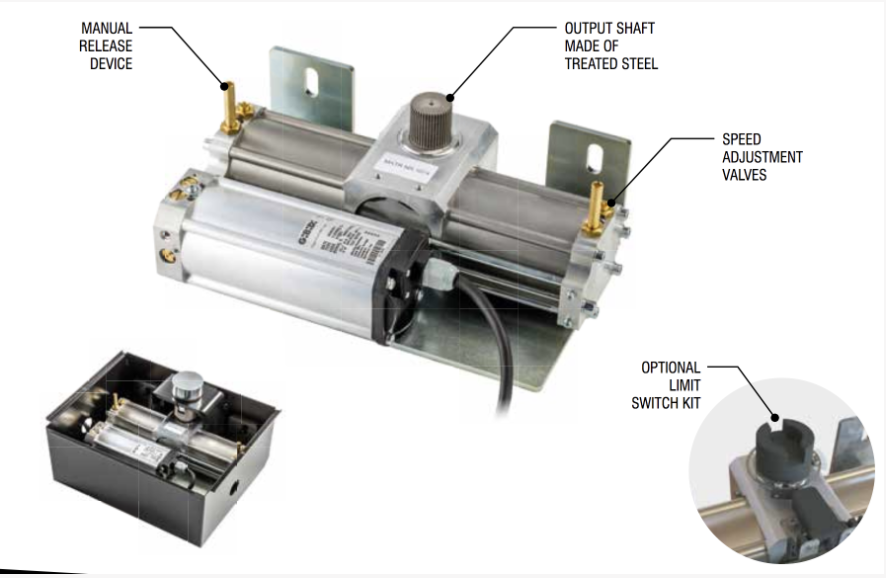

The new range has been designed with the aim of further improvements over the already high quality of previous models. Here you are the main improvements:

• Increased the size of the internal rack

• Double protection inserted around the transmission shaft

• New bronze guide ring for the transmission shaft

• Increased bearing robustness

• Inserted a thrust bearing on the transmission shaft

• New anchor system for the gearbox bushing

• New anchor system for the hydraulic power unit and the jack for greater resistance.

-

Old rack at the top new rack at the bottom

Old rack at the top new rack at the bottom -

On the left new stronger rack, thooth work 100% of their surface on the shaft. On the right, the FLO

On the left new stronger rack, thooth work 100% of their surface on the shaft. On the right, the FLO -

3 of the main new elements, new RACK

3 of the main new elements, new RACK -

Below the metal plate there are now 2 pins that made the jack to move together with the hydraulic u

Below the metal plate there are now 2 pins that made the jack to move together with the hydraulic u -

From the back of the operator you can see the ball bearing support in the bottom ( partially visible

From the back of the operator you can see the ball bearing support in the bottom ( partially visible -

Here you can see the matching of the rack and the shaft. Above the new bushing with bronze guiding r

Here you can see the matching of the rack and the shaft. Above the new bushing with bronze guiding r -

Here you can see the square shaped rack with guiding system into the gear body

Here you can see the square shaped rack with guiding system into the gear body -

GIBIDI FLOOR UNDERGROUND MOTORS

GIBIDI FLOOR UNDERGROUND MOTORS

Yes we do have new stock in !!!